Elevating Machining Efficiency: Analyzing the Capabilities of 4+4 Living Tool Turn-Mill CNC Lathe and Power Turret CNC Lathe

In the realm of precision machining, the choice between different CNC lathe configurations can significantly impact productivity, accuracy, and versatility. Two prominent contenders in this arena are the 4+4 Living Tool Turn-Mill CNC Lathe and the Power Turret CNC Lathe. Let's delve into a comparative analysis to understand their respective strengths and applications.

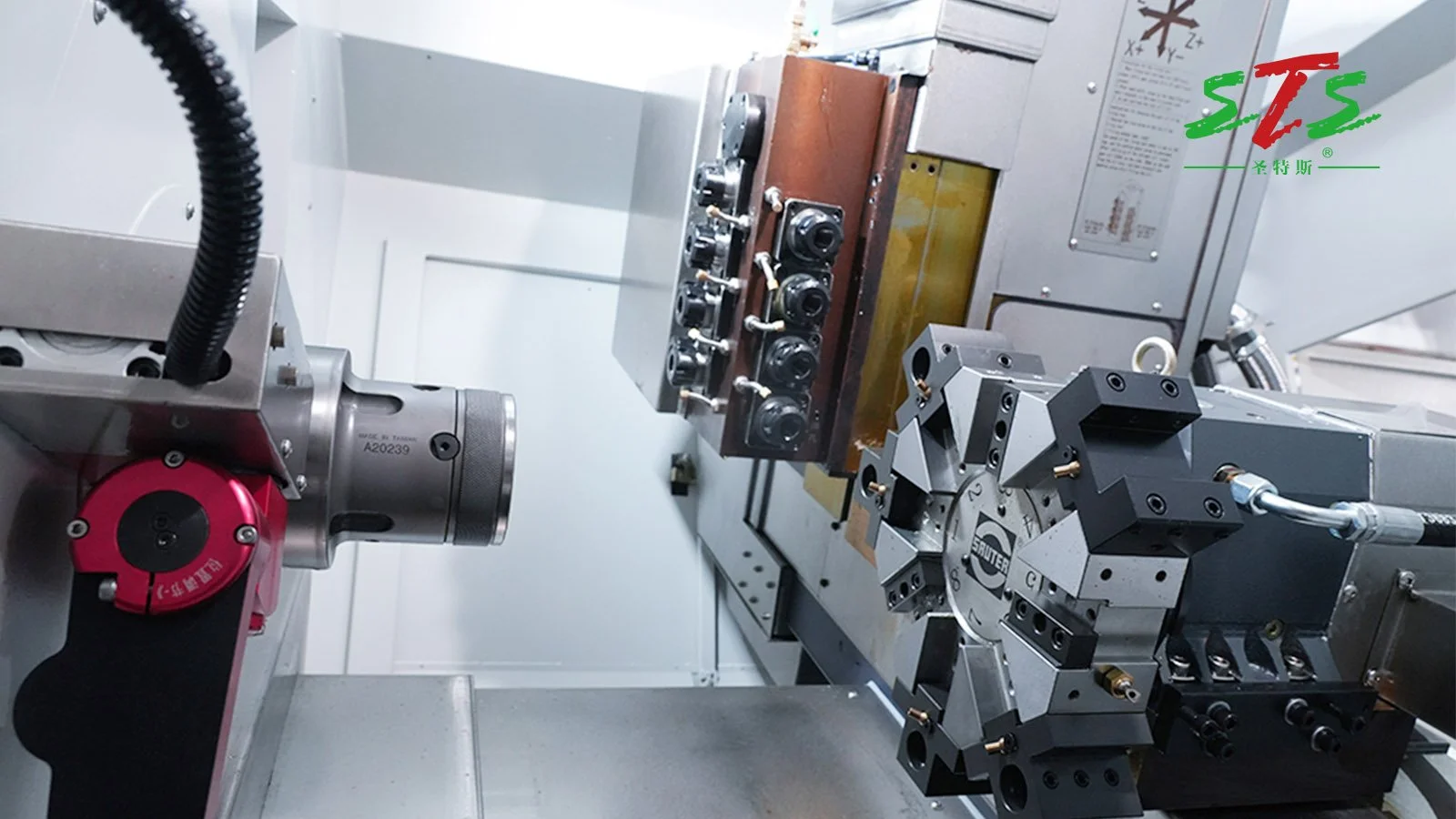

4+4 Living Tool Turn-Mill CNC Lathe:

The 4+4 Living Tool Turn-Mill CNC Lathe stands as a pinnacle of multifunctional machining excellence. It integrates the capabilities of both a lathe and a milling machine, enabling complex machining operations with unparalleled efficiency. Here's a closer look at its features:

Integrated Turning and Milling: Unlike conventional lathes, the 4+4 Living Tool system facilitates simultaneous turning and milling operations in a single setup. This eliminates the need for multiple machine setups, reducing production time and enhancing accuracy.

Living Tool Technology: The "Living Tool" mechanism equips the lathe with rotating tool stations, each capable of performing various machining functions. Elevating Machining Efficiency: Analyzing the Capabilities of 4+4 Living Tool Turn-Mill CNC Lathe and Power Turret CNC Lathe

Enhanced Flexibility: With live tooling capabilities, this lathe accommodates a wide range of machining processes, including drilling, tapping, and contouring. Its ability to handle complex workpieces with precision makes it ideal for industries such as aerospace, automotive, and medical.

Improved Workflow: By consolidating multiple machining operations into a single setup, the 4+4 Living Tool Turn-Mill CNC Lathe streamlines workflow and minimizes material handling. This results in faster production cycles and reduced lead times, enhancing overall productivity.

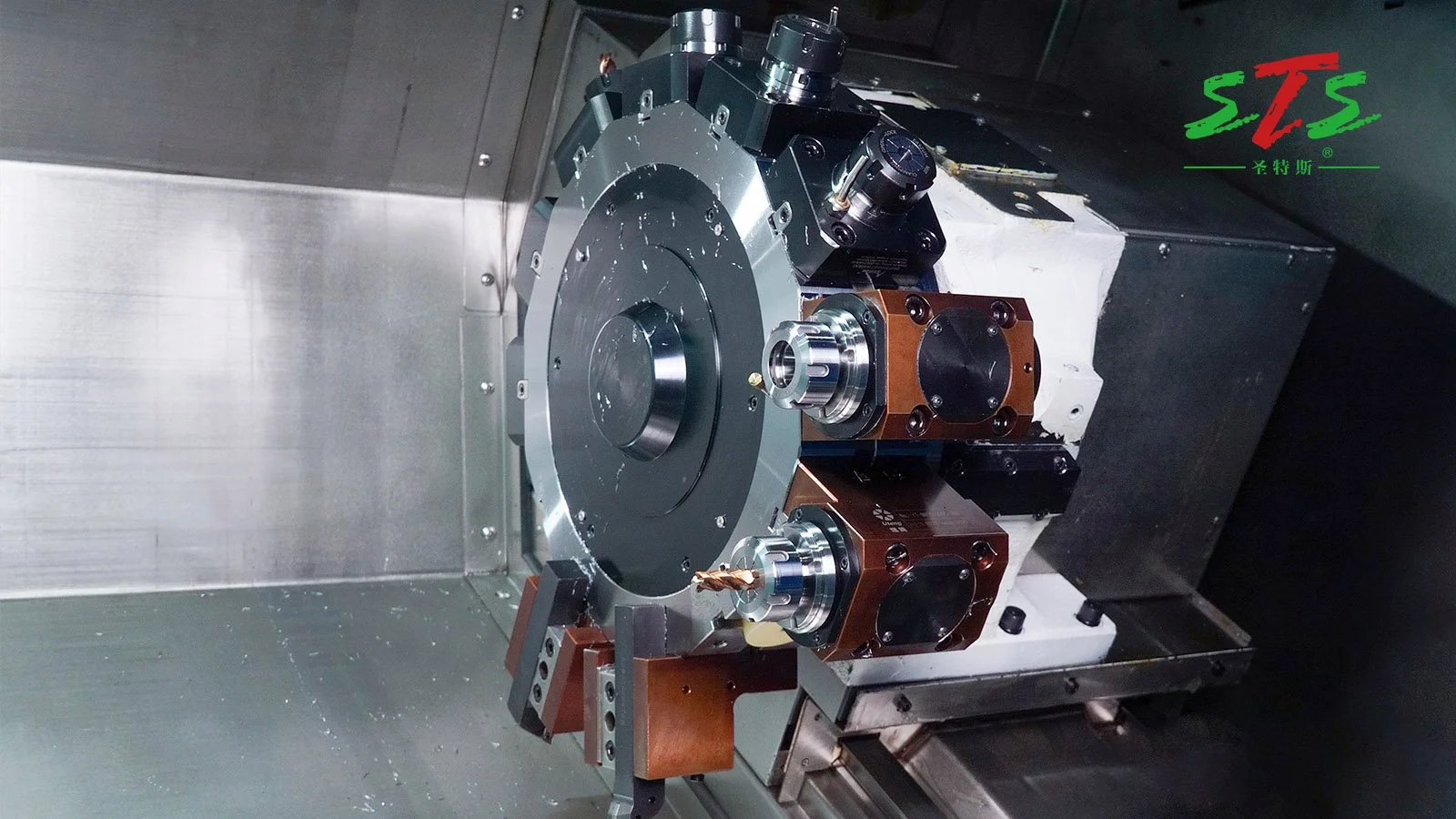

Power Turret CNC Lathe:

In contrast, the Power Turret CNC Lathe offers a more traditional yet efficient approach to machining operations. Let's explore its key attributes:

Quick Tool Changeover: Equipped with a power turret, this lathe enables rapid tool changes, optimizing production efficiency for high-volume machining tasks. The turret holds multiple tools simultaneously, allowing for a seamless transition between different cutting operations.

High Precision Turning: With its robust construction and precise tool positioning, the Power Turret CNC Lathe excels in turning applications that demand strict adherence to dimensional tolerances and surface finish requirements. It delivers consistent results across large production runs.

Cost-Effective Solution: While not as versatile as the 4+4 Living Tool system, the Power Turret CNC Lathe offers a cost-effective solution for businesses focused primarily on turning operations. Its simplicity and reliability make it a popular choice for various industries, including manufacturing and job shops.

Ease of Operation: Designed for user-friendly operation, this lathe is suitable for both seasoned machinists and operators with limited experience. Intuitive controls and programming interfaces enhance accessibility, ensuring smooth production workflows.

Conclusion

In conclusion, the choice between a 4+4 Living Tool Turn-Mill CNC Lathe and a Power Turret CNC Lathe depends on the specific requirements of the machining application. While the 4+4 Living Tool system offers unmatched versatility and efficiency for complex machining tasks, the Power Turret lathe excels in high-volume turning operations with its simplicity and reliability. By understanding the unique strengths of each system, can make informed decisions to optimize your CNC lathe machining process. If you have any further inquiries or requirements, please feel free to contact us.