Optimizing the Use of CNC Coolant-Considerations for CNC Coolant

Insufficient coolant concentration can lead to a number of problems, including bacterial development, shorter tool lives, and corrosion of the machine and workpiece.

Optimizing the Use of CNC Coolant-Understanding CNC Coolant

Despite the significant investment in CNC coolant for machine tools, many machine shops overlook the importance of coolant systems in their machining operations. Yet, the type and application of coolant are crucial for successful metalworking and an efficient machining process.

Key Clamping Considerations for CNC Lathes

The machining process of CNC lathes is similar to that of conventional lathes, but due to the fact that CNC lathes perform all turning operations in a single setup automatically, several aspects should be considered.

Basic Care and Maintenance of CNC Lathes

CNC lathes are advanced, complex machines blending machinery, electronics, and hydraulics. Maintenance is crucial to minimize failures and maximize performance. Maintenance personnel need expertise in machinery, processing, electronics, automation, and measurement to ensure effective upkeep and timely repairs.

Key Tips for Monitoring CNC Lathe Cutting

When it comes to making things with extreme precision, every little detail counts. Keeping a close watch on how our trusty precision CNC lathes do their cutting magic. Making sure everything runs smoothly and comes out, just right means paying attention to a few key things during the cutting process. Let's break down what those entails.

Elevating Machining Efficiency: Analyzing the Capabilities of 4+4 Living Tool Turn-Mill CNC Lathe and Power Turret CNC Lathe

In the realm of precision machining, the choice between different CNC lathe configurations can significantly impact productivity, accuracy, and versatility. Two prominent contenders in this arena are the 4+4 Living Tool Turn-Mill CNC Lathe and the Power Turret CNC Lathe. Let's delve into a comparative analysis to understand their respective strengths and applications.

The Power Turret of CNC Lathe

With the development of the manufacturing industry, CNC lathes, as efficient and precise processing equipment, have become an indispensable part of modern factories. Among the many components of CNC lathes, the power turret plays a particularly prominent role, providing higher precision and efficiency for workpiece processing.

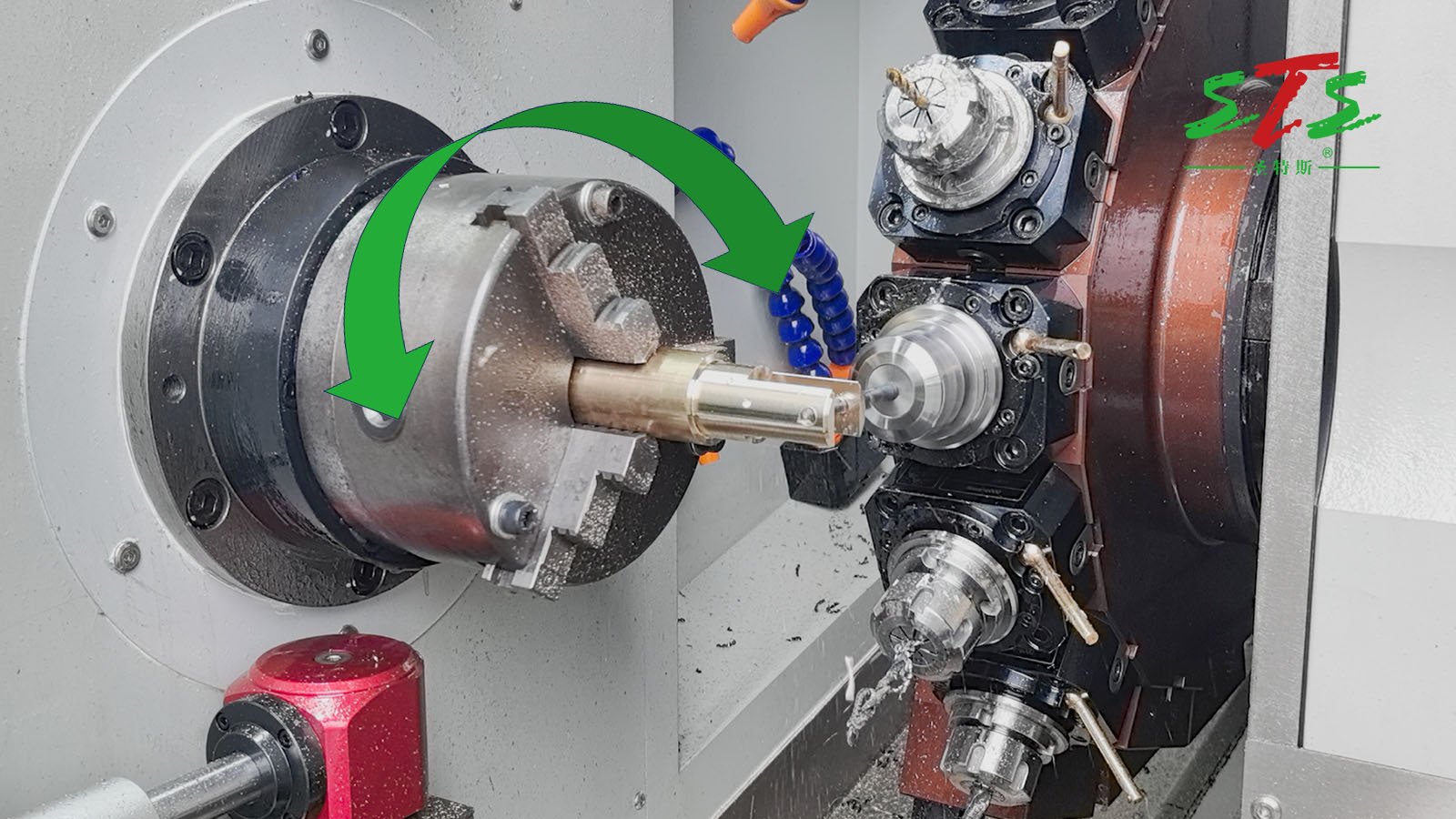

The Functionality of the C Axis in CNC Lathe

The functionality of the C axis in a CNC lathe refers to its ability to rotate the workpiece along its axis during the machining process. This rotational capability provides the lathe with enhanced versatility, allowing it to perform a broader range of operations with greater precision.

How to Choose the Tools for CNC Lathes?

CNC lathe processing is a high-precision work, and its processing procedures are concentrated and the number of parts clamping is small, so it puts forward higher requirements for the CNC tools used.

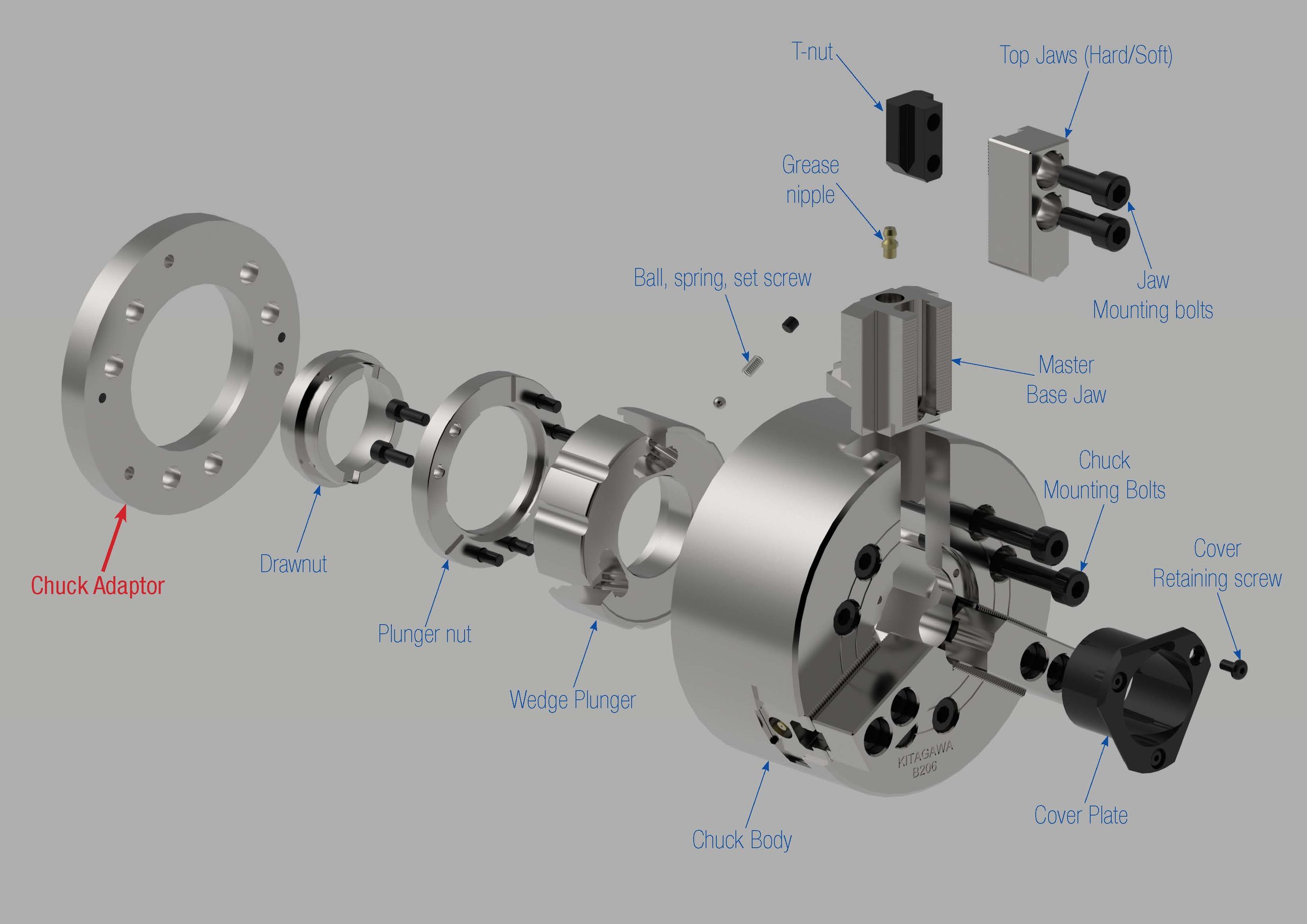

Three-jaw Chucks or Collet Chucks? Which is Better?

For your CNC turning machine, is a collet chuck or a standard 3-jaw chuck the better option? As is the case with many decisions, the response is: It depends.

How to Choose and Arrange CNC Lathe Tools?

Tool selection and cutting amount determination in CNC machining are completed under human-computer interaction, which is in sharp contrast to ordinary machine tool processing. It also requires programmers to master the basic principles of tool selection and cutting amount determination. When programming fully considers the characteristics of CNC machining and can correctly select cutting tools and cutting amounts.

Classification and Characteristics of CNC Tools

CNC machining tools must adapt to the high speed, high efficiency, and high degree of automation of CNC machine tools. They should generally include universal tools, universal connecting tool holders, and a small number of special tool holders. The tool holder is connected to the tool and mounted on the machine tool power head, so it has been gradually standardized and serialized. There are many ways to classify CNC tools.

Slant Bed CNC Lathe vs Flat Bed CNC Lathe

Heavy-duty turning is done mostly on flat bed CNC lathes, which are frequently utilized to work with complex geometries, short shafts, discs, and other objects. It can also machine a wide range of internal and external threads in either metric or imperial units. The rotary head can mill or drill the workpiece's circumferential and end face when it is positioned on the flat bed CNC lathe. The flat bed CNC lathe can drill, ream, extend, and roll in addition to turning the outer circle, slotting, and chamfering. It is stable and productive, and it has a great machining range.

Features and Applications of CNC Lathes

CNC machine tool is the abbreviation of digital control machine tool. It is an automated machine tool equipped with a program control system. The control system can logically process programs with control codes or other symbolic instructions and decode them to make the machine tool move and process parts.

CNC Lathe Chamfering Programming Skills

Many people feel that the manual programming of CNC lathes encounters arcs, and chamfers, and calculates the point coordinates of the time more cumbersome. Today's article shares two knowledge points so that you program to save worry and effort.

Identifying a Lathe Spindle Nose Chart

Look at the diagrams below to determine what kind of spindle nose you have. Analyze the associated chart, then take the required measurements. Select the spindle nose size for your chuck or adapter plate.

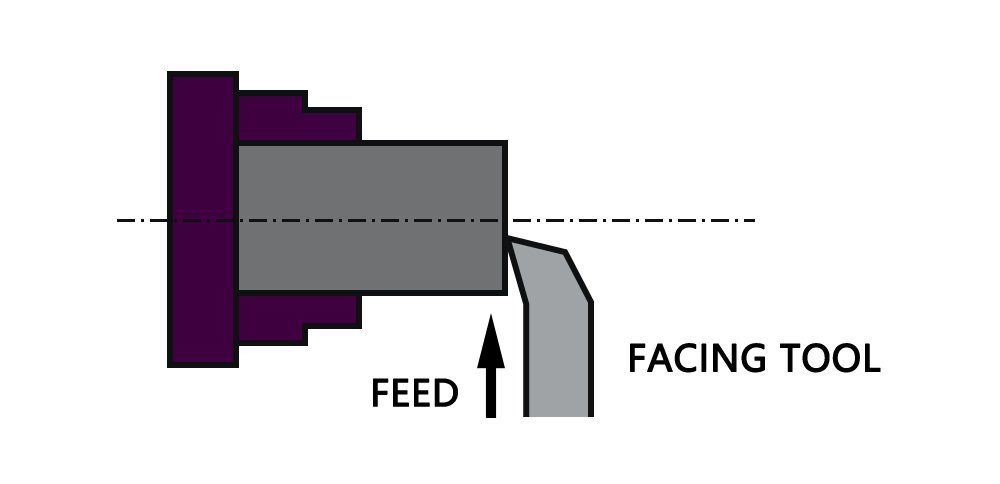

What activities take place in a CNC lathe?

Undoubtedly, CNC lathes are the most popular lathes available today. Let's learn more about them. Due to its quick and precise operation, CNC, or computerized numerical control, is a term that is frequently used to refer to a lathe in modern society.

A computer program controls the machine tool. The program starts operating at a rapid rate and with excellent precision as soon as it is loaded into the computer. There is also a machine that has been preplanned and programmed; once the code for the various jobs is set, the machine can start working without the need to update the code again. Once it has been put up, a semi-skilled worker may easily operate it. Capstan and turret-style lathes are also used in mass production, although they lack a programmed feeding system. The components made by these lathes have incredibly small dimensional tolerances.

What is CNC LATHE

A lathe is typically used in glass-making, metalworking, thermal spraying, metalworking, metal spinning, and woodturning. The workpiece is usually held by one or two centers, at least one of which can be shifted horizontally to accommodate workpieces of various lengths. Older production lathes are being quickly replaced by CNC lathes because of their simplicity in setup, use, repeatability, and accuracy. One sort of CNC machining is CNC lathe work.

Wedge-Type Y-Axis CNC Lathe VS Real (True) Y-Axis CNC Lathe

Wedge-Type Y-Axis CNC Lathe: The wedge-type Y-axis mechanism utilizes a wedge block to position the tool off-center, enabling Y-axis movement. It allows for off-center drilling, milling, and other complex machining operations.

What is the difference between Gang Type CNC Lathe, power turret CNC lathe, and living tool turning-milling composite CNC lathe

CNC lathes have become essential tools for several industries in modern manufacturing. Three popular variations with various benefits and features are live tool turn-mill CNC lathes, power turret CNC lathes, and gang type CNC lathes. In-depth examinations of these machines' benefits, features, and uses are covered in this essay, allowing manufacturers to decide which ones to use based on their own needs.