Three-jaw Chucks or Collet Chucks? Which is Better?

For your CNC turning machine, is a collet chuck or a standard 3-jaw chuck the better option? As the case with many decisions, the response is: It depends.

The benefits and drawbacks of every kind of chuck need to be taken into account in relation to your application's lots sizes, material types, range of diameters, workpiece lengths, and dimensional tolerances, etc. Consider the following facts:

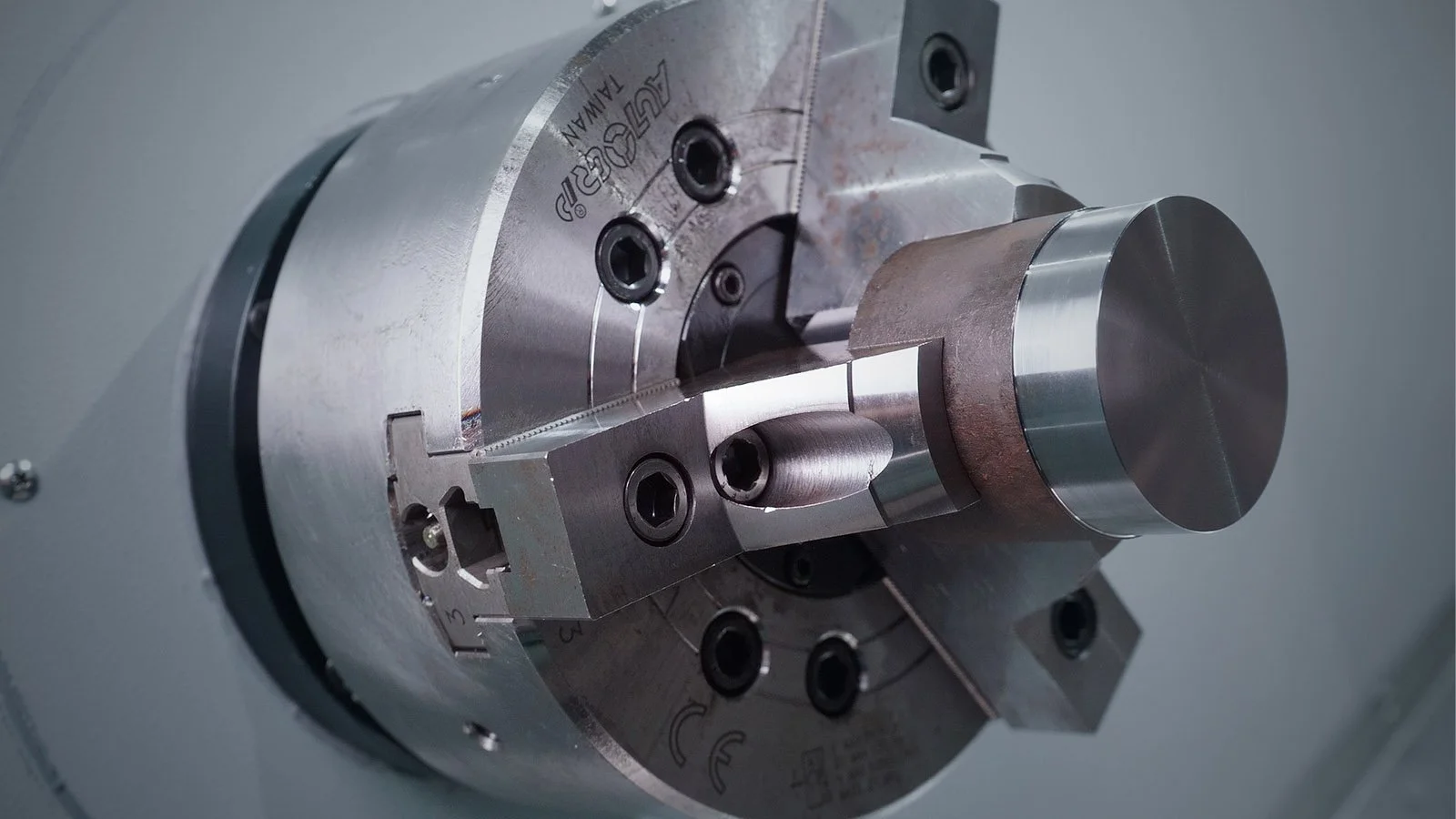

Versatility

If you're handling multiple tasks with various workpiece diameters, Three-jaw chucks might be the best option. Smaller workpieces, usually 3" or less in diameter, are the ideal fit for collet chucks. Longer workpieces are also better suited for 3-jaw chuck machining because the longer collet chuck restricts Z-axis travel.

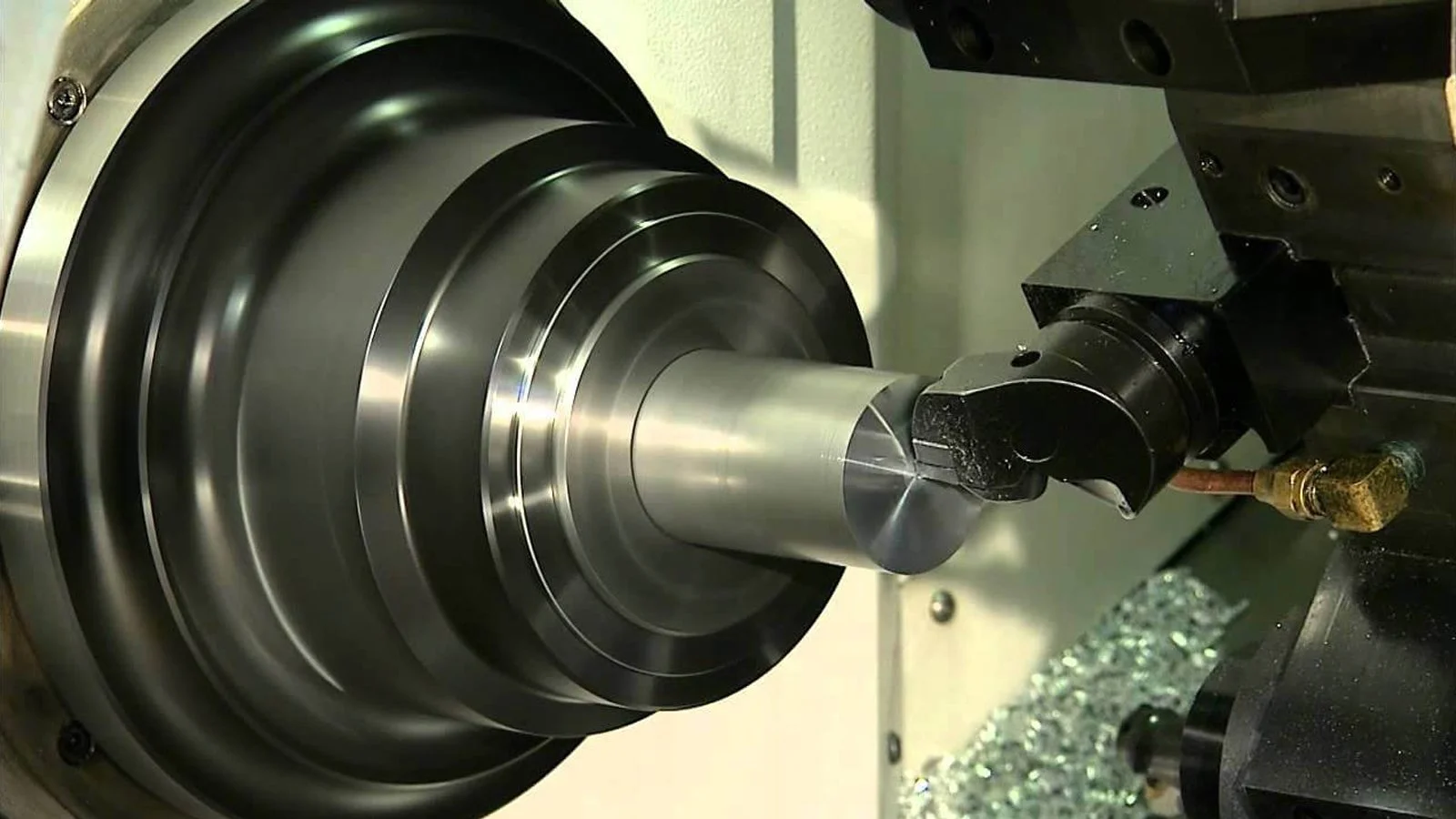

Spindle performance:

The lathe spindle accelerates more quickly and requires less effort from the spindle motor because collet chucks are lighter and have less mass. Furthermore, handling heavier workpieces at higher spindle RPMs is made possible by the lighter collet chuck.

Tight tolerances

Collet chucks are less impacted by centrifugal force when used for high precision work because they retain an equal clamping force around the workpiece rather than at just three points. Better accuracy and concentricity are thus made possible.

Transitions

Everything is dependent on how you apply. Collet chucks don't usually take as long to change, but 3-jaw chucks can handle a wider variety of diameters without the need for changeovers.

Of course, choosing the right chuck type involves taking into account a variety of additional factors in addition to those that influence the productivity of CNC machines.