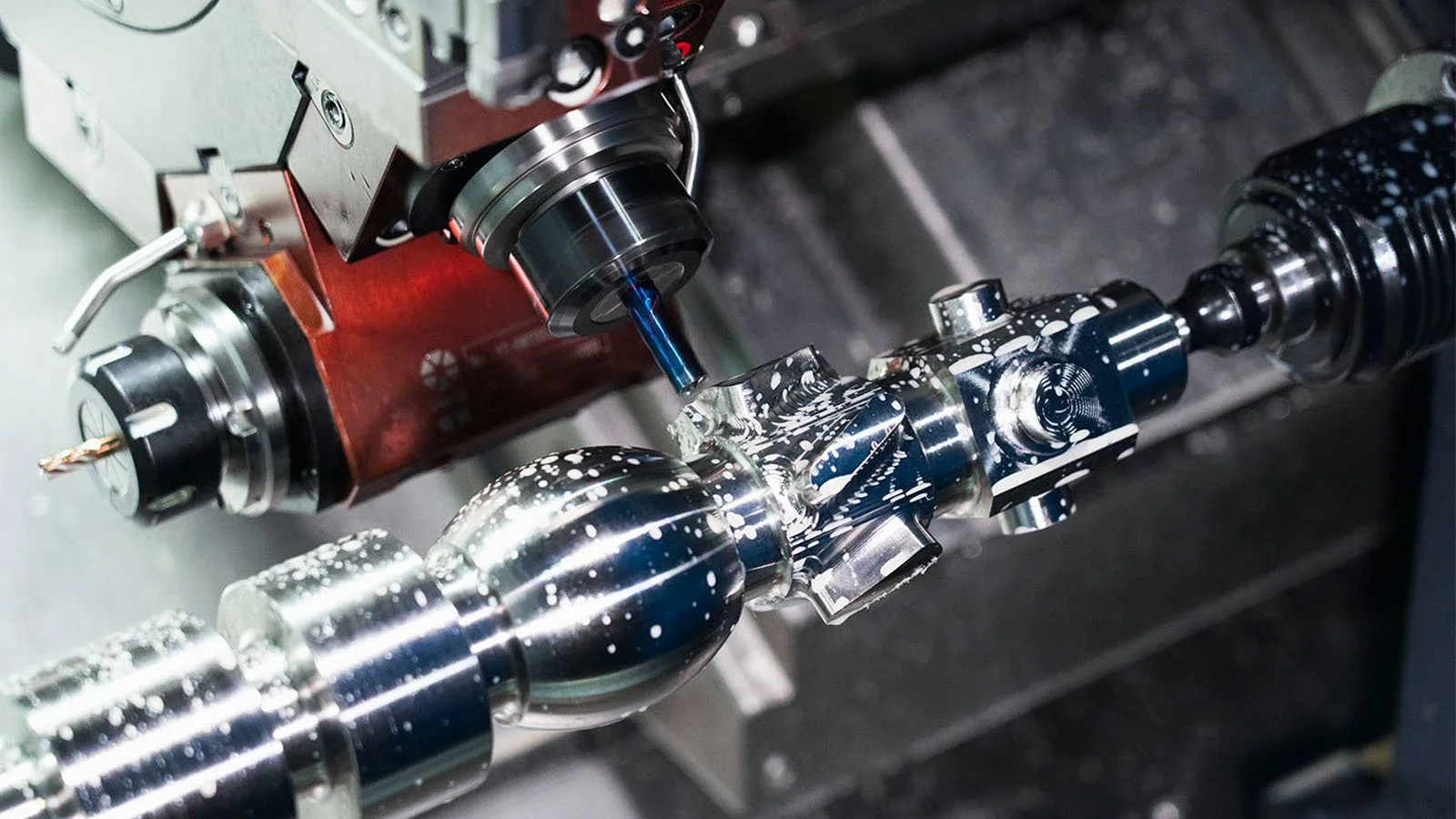

Features and Applications of CNC Lathes

CNC lathe features

CNC machine tool is the abbreviation of digital control machine tool. It is an automated machine tool equipped with a program control system. The control system can logically process programs with control codes or other symbolic instructions and decode them to make the machine tool move and process parts.

Compared with ordinary machine tools, CNC machine tools have the following characteristics:

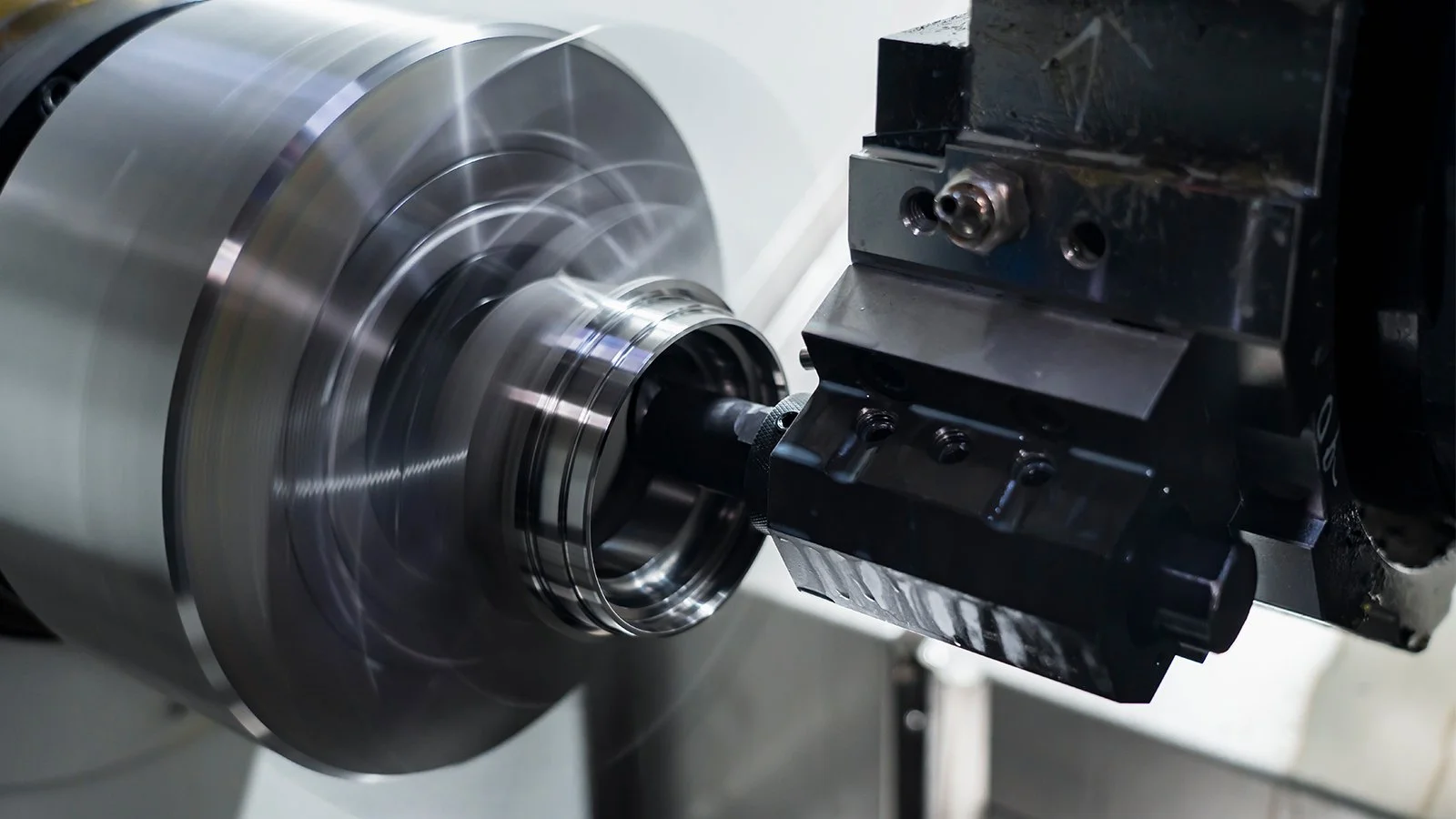

High processing precision and stable processing quality. The CNC machine tool itself has high manufacturing precision, and it automatically processes according to predetermined procedures, so human operation errors are avoided and the consistency of the same batch of parts is good.

High productivity. It can process multiple parts of the part in one clamping, eliminating many intermediate processes (such as marking, etc.) and greatly shortening the production preparation time.

The high degree of automation. In addition to blank processing and clamping, almost all processing parts can be automatically completed by machine tools, reducing the operator's labor intensity and improving working conditions.

Adaptable. CNC machining generally does not require very complex process equipment. When the processing object changes, the program can be changed. Generally, the parts can be processed without redesigning the tooling.

Facilitates the modernization of production management. CNC machine tools process parts, which can accurately calculate the processing hours of parts, and simplify the inspection and management of tool fixtures and semi-finished products, which is conducive to the modernization of production management.

CNC machine tools are high in cost, technically complex, and difficult to maintain, and require high-quality operating and management personnel.

Application of CNC machine tools

CNC machine tools have many advantages that ordinary machine tools do not have. Its application scope is constantly expanding, but it cannot completely replace ordinary machine tools, nor can it solve all problems in mechanical processing most economically.

CNC machine tools are most suitable for processing parts with the following characteristics:

Multiple varieties, small sizes Mass produced parts.

Parts with complex shapes and structures.

Parts that require frequent modifications.

Critical parts that are expensive and are not allowed to be scrapped.

Design and manufacture urgently needed parts with a short manufacturing cycle.

Parts with large batches and high precision requirements.