Importance of wedge type section and Y-axis in mill-turn CNC lathes

Introduction:

Precision, efficiency, and adaptability are critical success criteria in today's industrial sector.

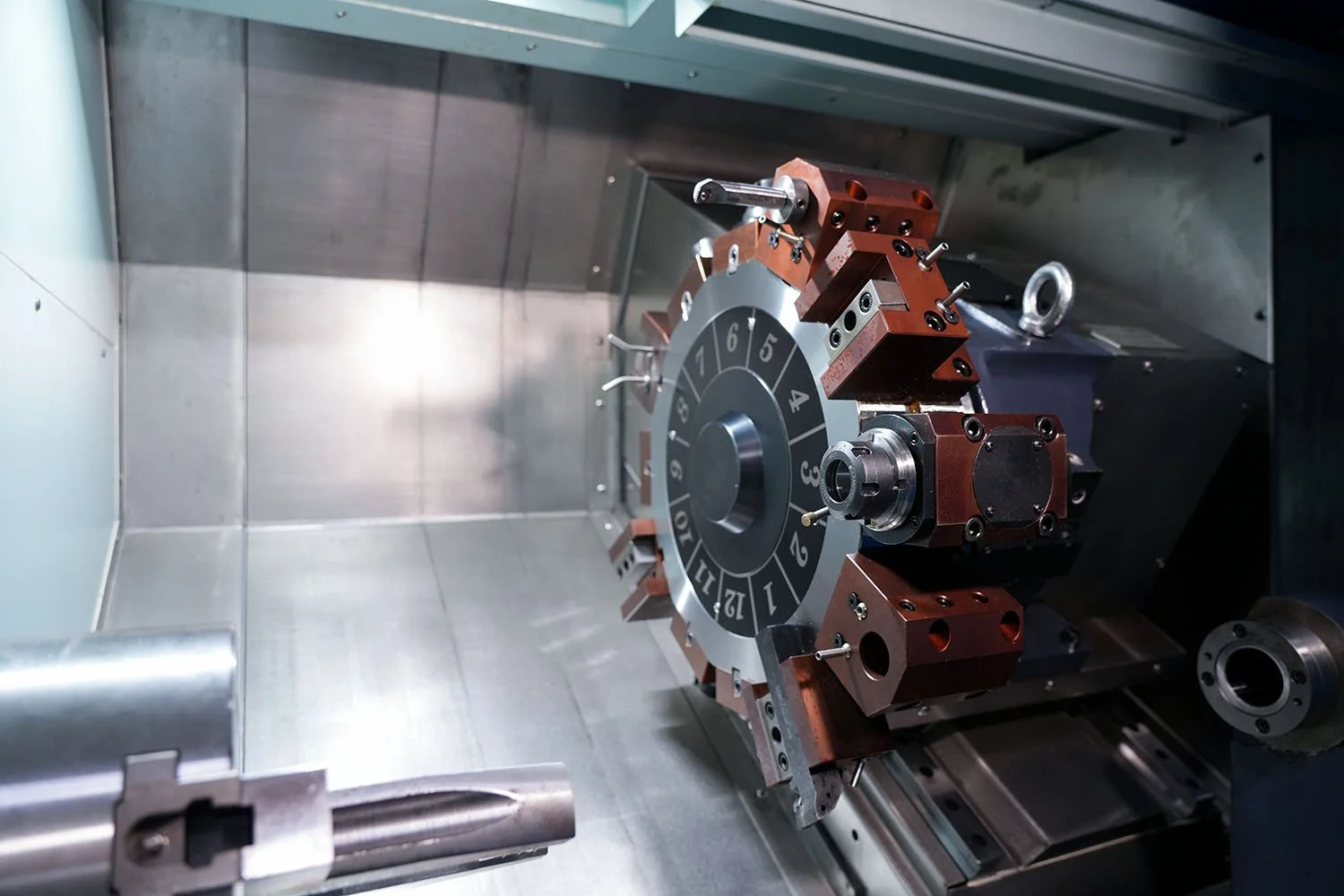

Turn-mill CNC lathes have revolutionized the industry by fusing the capabilities of a lathe and a milling machine into one powerful machine. The incorporation of interpolation and the Y-axis stands out as a crucial improvement among their many advanced features.

This essay examines the significance of wedge type section and the Y-axis in turn-mill CNC lathes in detail, highlighting its advantages, uses, and significant influence on contemporary manufacturing processes.

What is Wedge type section ?

The idea of wedge type is at the core of intricate machining operations.

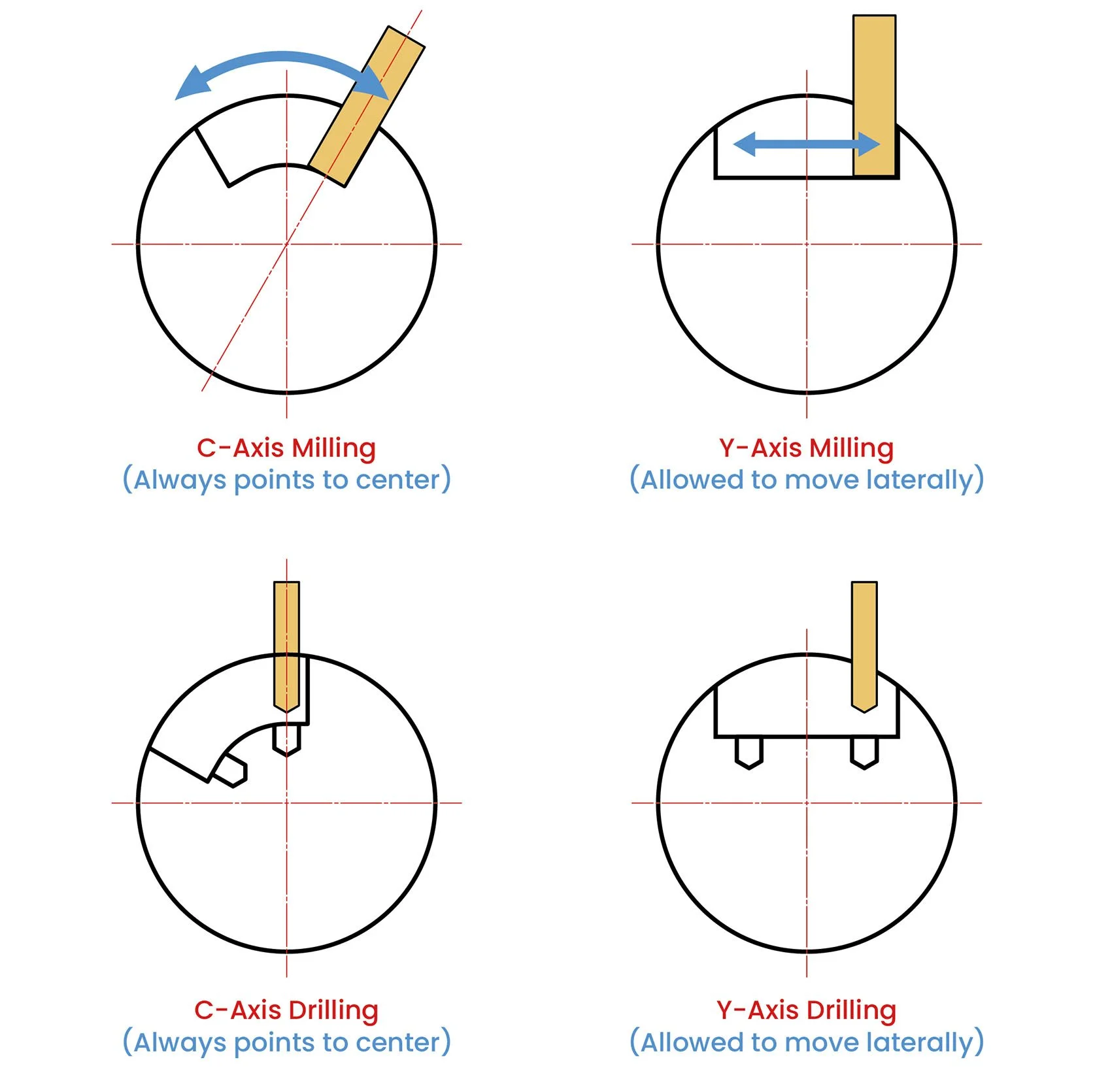

In a CNC machine, wedge type is the coordinated motion of several axes that makes it possible to execute complex tool paths. Wedge type in turn-mill CNC lathes requires coordinated movement of the X, Y, and Z axes.

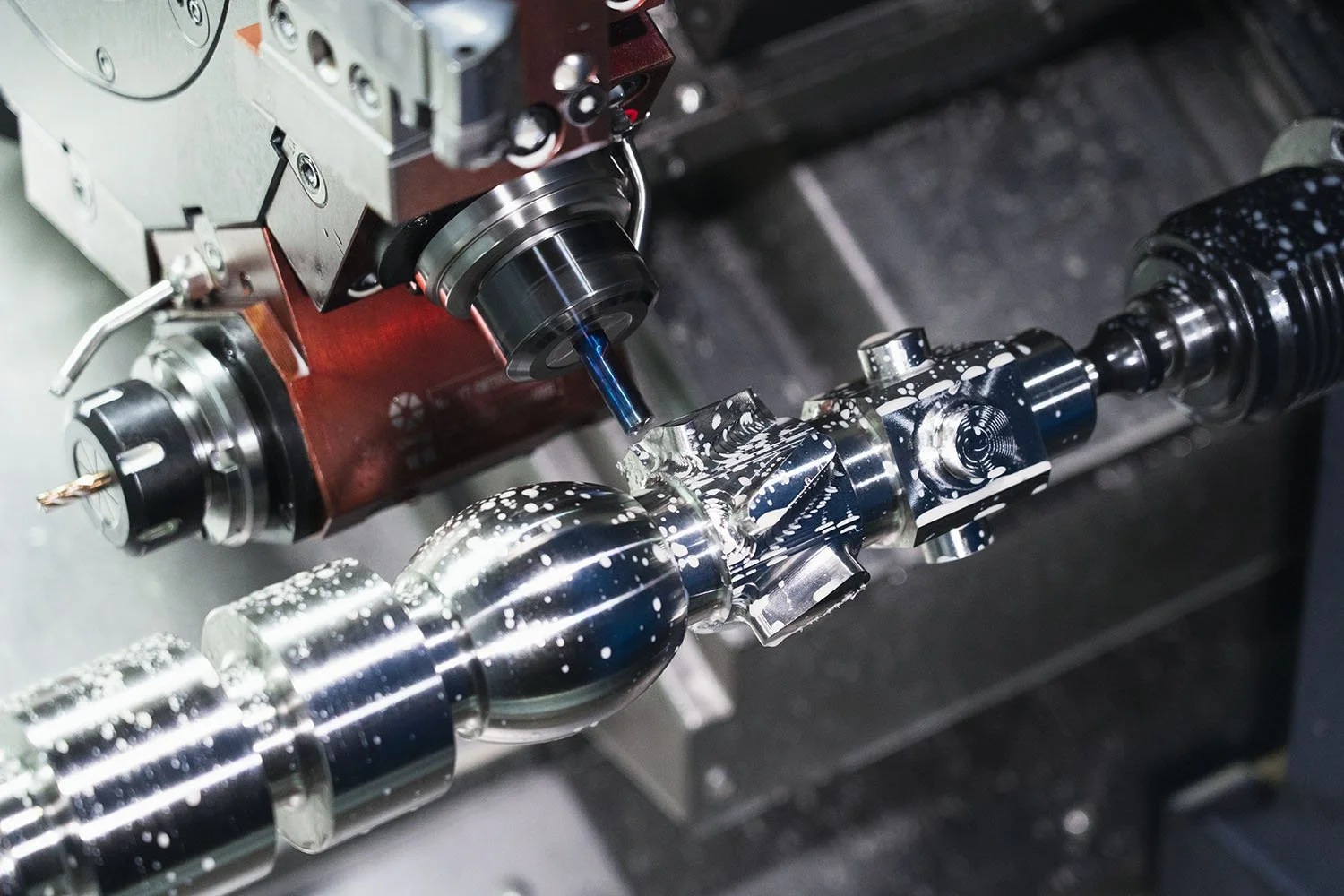

Manufacturers are now able to create intricate geometries, curves, and features that were previously impossible to obtain with conventional machining techniques.

The Y-Axis Function

When using turn-mill CNC lathes, the Y-axis plays a crucial role. The Y-axis adds a third degree of freedom because it is a linear axis that is parallel to the X and Z axes.

This extra axis enables side-to-side movement of the milling spindle or tool turret, increasing the variety of machining processes.

Turn-mill CNC lathes may now conduct milling operations including drilling, tapping, slotting, and contouring on a single machine setup, simplifying production and obviating the need for additional machines.

Benefits and advantages of wedge type and Y-axis

Manufacturers can gain a wide range of advantages from turn-mill CNC lathes that use wedge type and the Y-axis.

First off, the necessity for time-consuming and error-prone transfers between several machines is eliminated when multiple machining operations are combined into a single machine setup. Significant cost savings result from the workflow being streamlined and the production time being decreased.

Additionally, the concurrent use of several axes improves accuracy and precision, ensuring the manufacture of completed products of the highest caliber.

Engineers and designers now have more design options because to the Y-axis. Previously difficult to obtain complex shapes and contours are now quite simple to achieve. Manufacturers are now more able to take on difficult projects and create components with higher levels of complexity, which encourages innovation and pushes the limits of what is possible in the manufacturing industry.

Uses in Contemporary Manufacturing

Turn-mill CNC lathes with wedge type and the Y-axis are extremely useful in a variety of industries due to their adaptability.

The areas of precision engineering, aerospace, automotive, and medicine are the main benefactors of these cutting-edge machines. These sectors require the manufacturing of intricate, precise components. Turn-mill CNC lathes speed up production, save production time, and boost overall productivity by allowing for simultaneous turning and milling operations.

These lathes let manufacturers to satisfy the exacting standards of contemporary industries for everything from delicate engine parts to medical implants.

PT52S

Max. Workpiece Size: Φ300x350mm

3355mm*1920mm*2156 mm

PT52W

Max. Workpiece Size: Φ350x550mm

3030mm*2018mm*2032mm

Effect on Production Efficiency

The efficiency of manufacturing has significantly increased as a result of the integration of wedge type and the Y-axis in turn-mill CNC lathes. Manufacturers can drastically minimize setup times, tool changes, and material handling by merging numerous machining operations into a single machine. This leads to increased productivity and better use of resources, which reduces costs and accelerates lead times. Simultaneous complicated milling and turning operations increase machine utilization and decrease downtime, thereby boosting output and profitability.

Conclusion:

Turn-mill CNC lathes have undergone a revolution thanks to wedge type and the Y-axis, ushering in a new era of precision manufacturing.

Complex machining now has countless options thanks to the coordinated movement of several axes and the addition of the Y-axis for milling operations. Manufacturers can create sophisticated designs, shorten manufacturing times, and offer high-quality components across a variety of sectors with improved precision, efficiency, and adaptability.

Turn-mill CNC lathes with wedge type and the Y-axis will remain at the forefront of contemporary manufacturing as technology develops, influencing the direction of precision machining and pushing the envelope of what is conceivable.