POWER TURRET CNC LATHE

PT72W

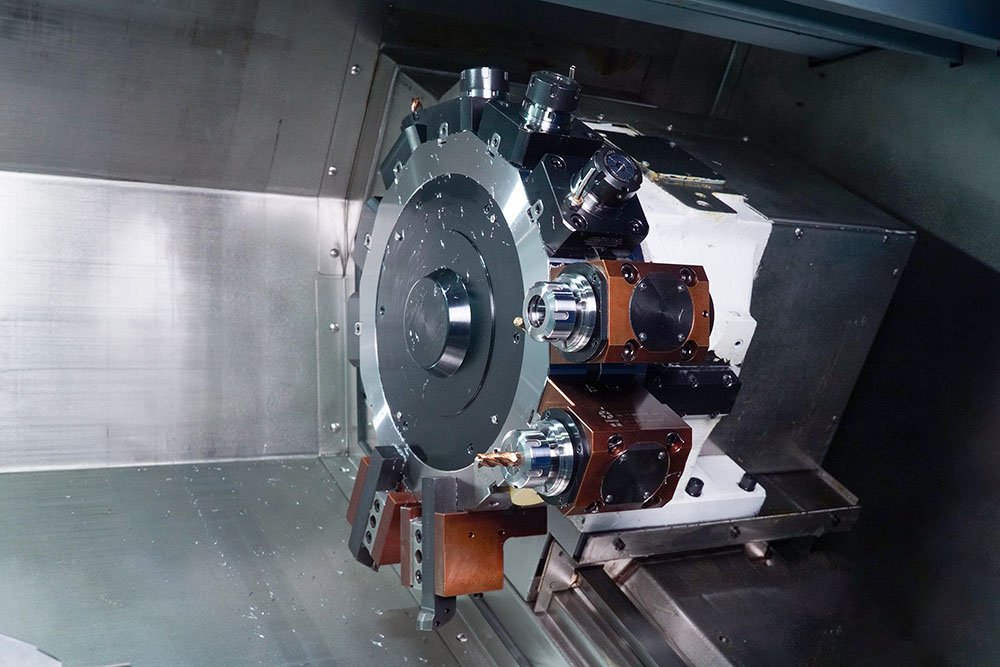

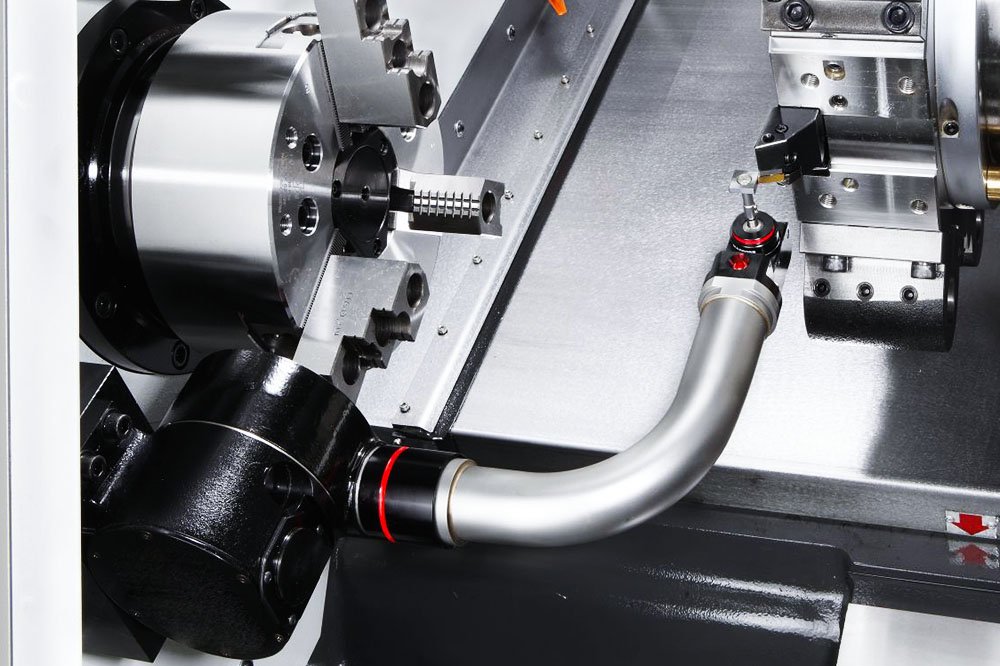

The PT72W is a CNC lathe equipped with a 12-station power turret. The Y-axis is designed with Wedge type, which has the advantage of high rigidity. The machine uses the latest SYNTEC control system, which is easy to operate and guarantees long and stable operation.

| Techical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features | ||||||||||

|

||||||||||

| Optional | |||||||||||||||

|

|||||||||||||||

Application

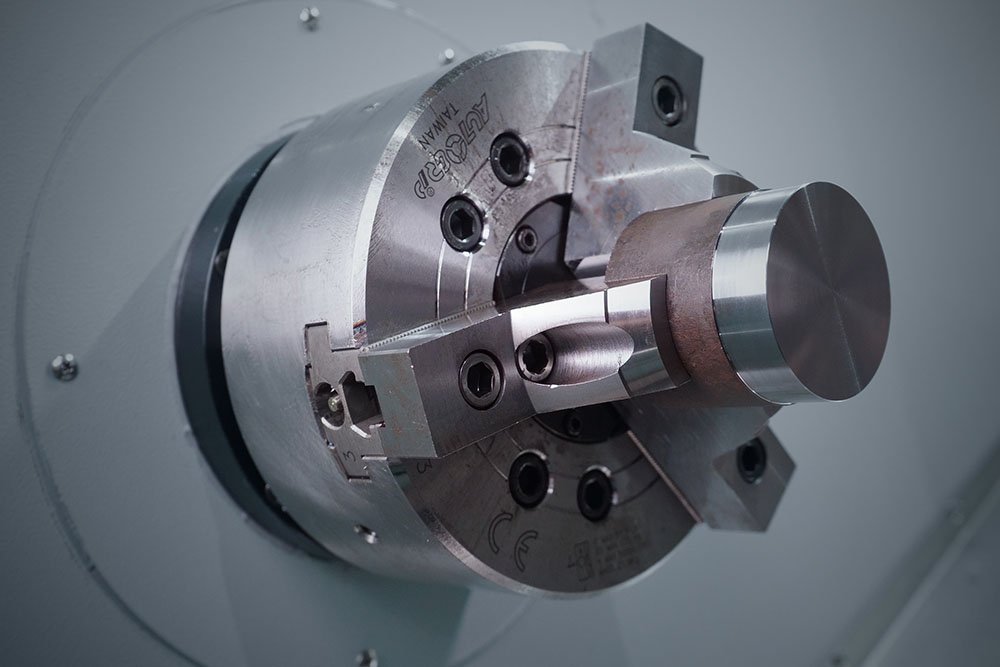

Competent to handle the turning process with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with bars diameter up to Φ71 mm or single workpieces up to Φ350mm. High Rigidity casting iron body provides the possibility of higher hardness materials and better smoothness (smaller roughness).