Application

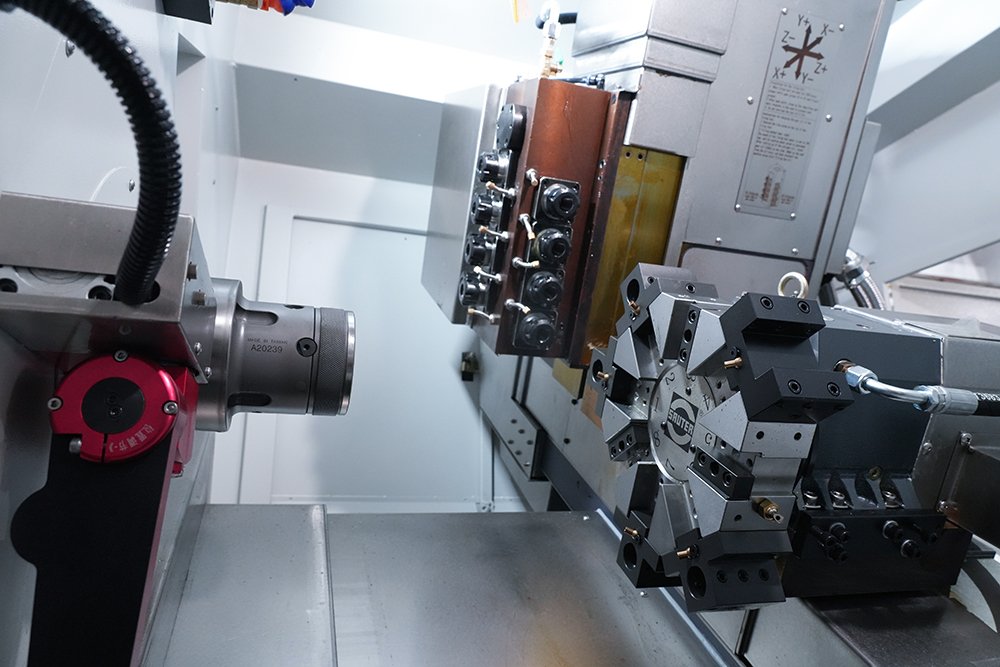

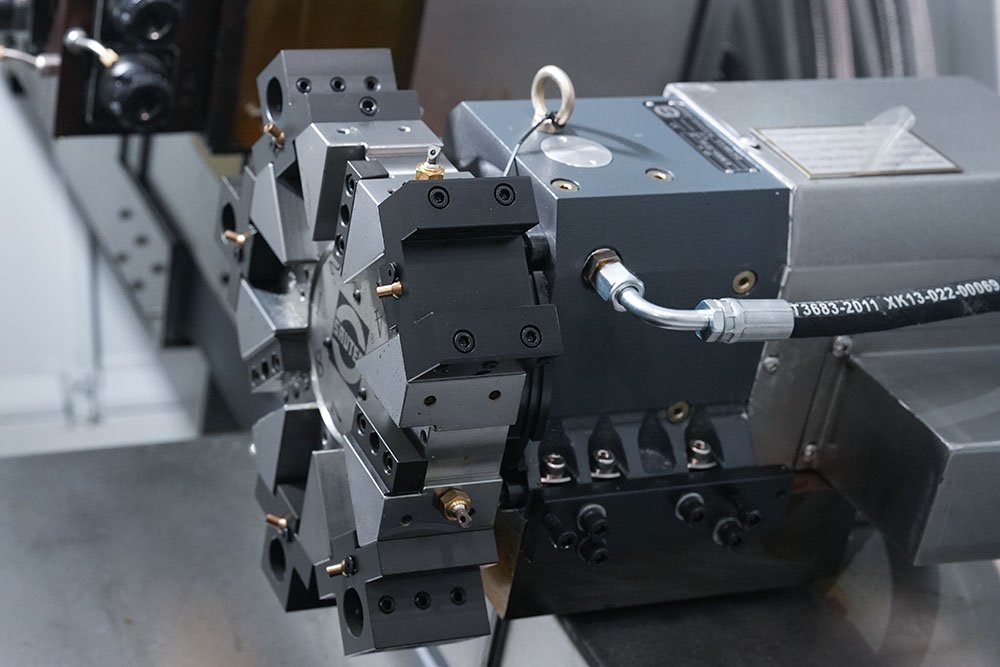

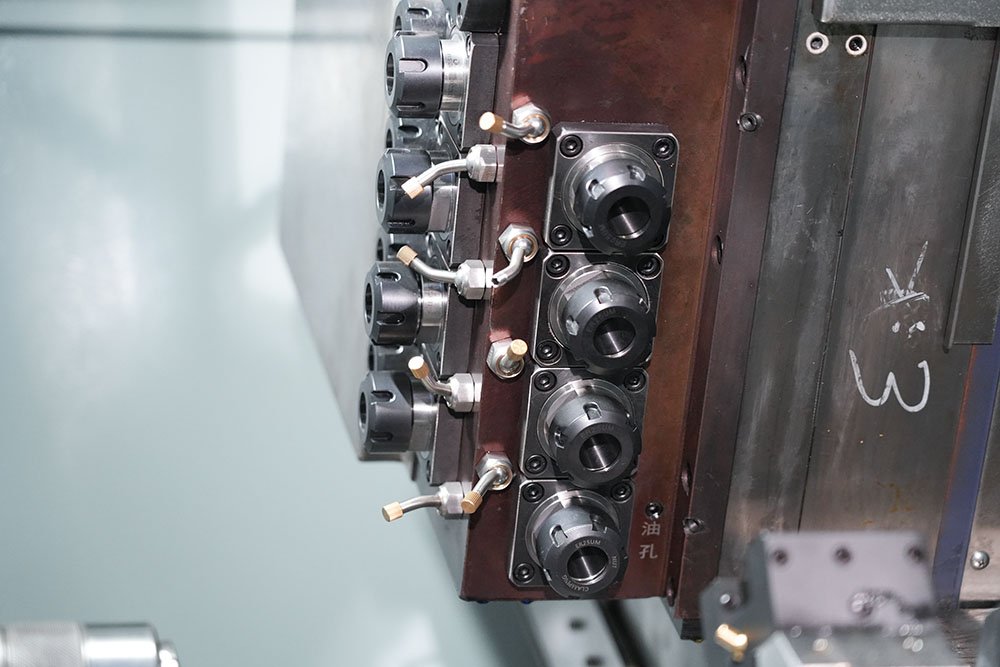

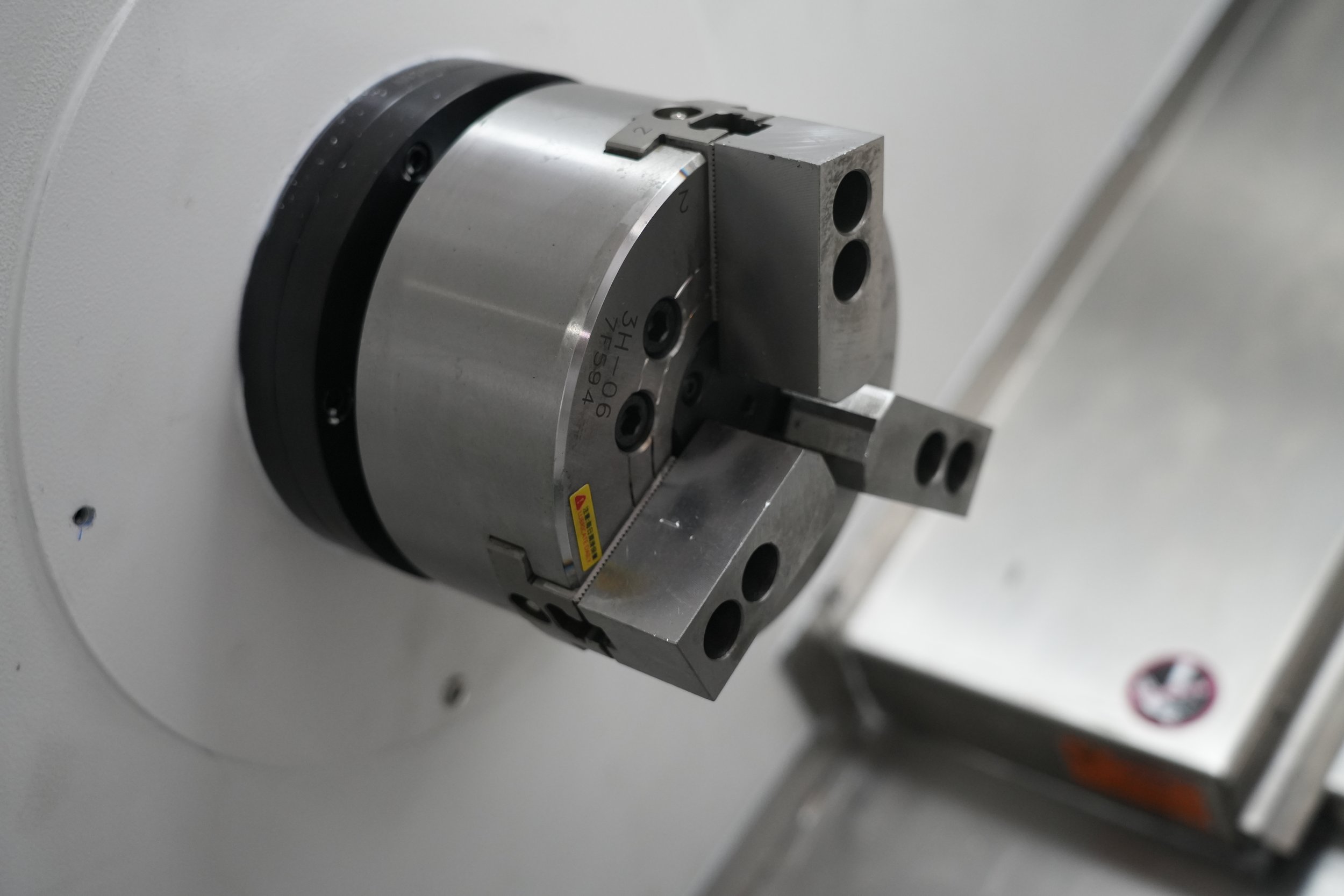

Competent to handle the turning process with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with bars diameter up to Φ45 mm or single workpieces up to Φ150mm. High Rigidity casting iron body provides the possibility of higher hardness materials and better smoothness (smaller roughness). TM46Y is equipped with a CNC program-controlled hydraulic tailstock, a 8-station servo turret, a 4+4 Y-axis living tool, suitable for long-axis turning, milling, Processing of complex multi-process products such as drilling and tapping.